Edison LED Lighting

Projects

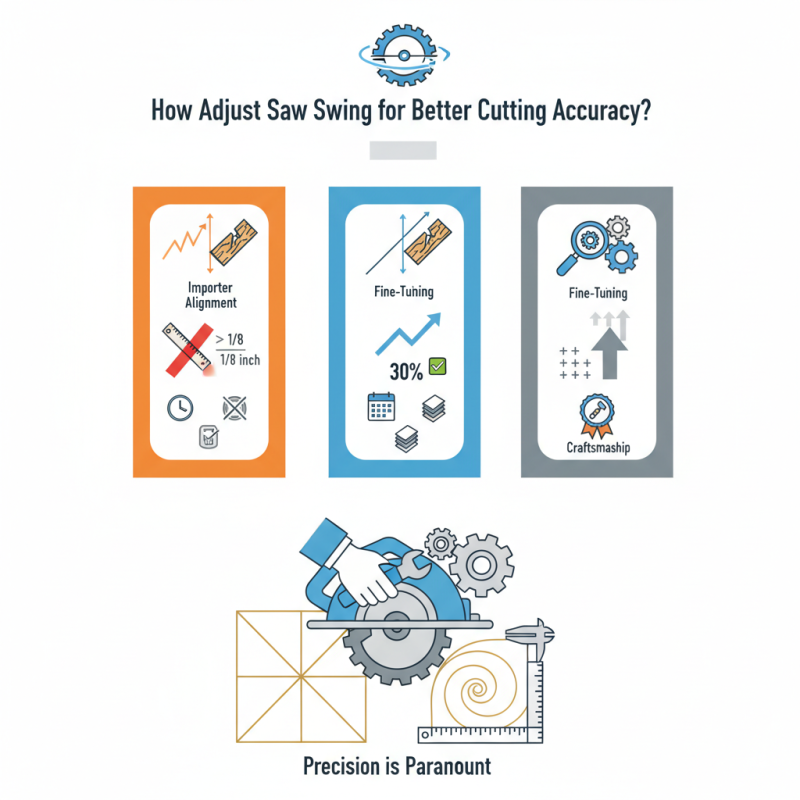

How to Adjust Saw Swing for Better Cutting Accuracy?

Achieving precise cuts in woodworking relies heavily on adjusting the saw swing. Research shows that improper saw swing can lead to cuts that deviate by more than 1/8 inch, impacting overall project quality. Studies indicate that consistent adjustments can enhance accuracy by up to 30%.

When the saw swing is misaligned, operations become inefficient. This not only wastes materials but also extends project timelines. The importance of regular checks cannot be overstated; mechanics often neglect this detail, resulting in costly errors.

Understanding how to fine-tune saw swing contributes to achieving tighter tolerances. Each slight adjustment may seem trivial but cumulatively, they make a significant difference. Embracing a methodical approach towards these adjustments can lead to enhanced craftsmanship and improved results. In woodworking, precision is paramount, and every detail matters.

Understanding the Importance of Saw Swing in Cutting Accuracy

Saw swing plays a crucial role in achieving precise cuts. The angle at which a saw blade swings significantly influences the overall accuracy. A report from the National Association of Manufacturers indicates that improper saw swing can lead to cutting errors of up to 3.5 mm in woodwork and even more in metal applications. This inconsistency can add costly delays and increases material waste, which is a core concern for professionals.

Adjusting saw swing requires a careful assessment of both the machinery and the material. Rigorous testing is essential to determine the ideal angle for each specific application. For instance, some users report difficulty maintaining consistent tension. This observation often leads to uneven cuts, highlighting the importance of regular calibration. It’s not just about making cuts; it’s about making the right cuts.

Moreover, many operators overlook the minor adjustments that can improve performance. A millisecond of delay in swing motion can result in flawed designs. A study published in the Journal of Manufacturing Processes notes that operators should continually reflect on their setup. Even small changes in swing angle can yield vastly different outcomes, showcasing the fine line between success and error in cutting processes.

Identifying the Optimal Saw Swing Angle for Different Materials

When it comes to cutting accuracy, the saw swing angle matters significantly. Different materials require different swing angles to achieve optimal results. For instance, studies show that a swing angle of 10 to 15 degrees works best for softwoods. These woods include pine and cedar. They are forgiving and easier to cut. However, harder hardwoods like oak may need a swing angle closer to 20 degrees. Such angles help reduce tear-out and improve finish quality.

It's crucial to experiment with angles when dealing with various materials. A 2018 industry report found that adjusting the angle correctly can increase cutting efficiency by up to 30%. However, this requires thoughtful tweaking. If the angle is too steep, cuts can be brittle and jagged. If it's too shallow, the tool may bind or stall. Each project may give feedback that prompts reflection on technique.

Take time to assess your cuts after making adjustments. Measure the outcomes against your expectations. Reflect on what’s working and what isn't. Sometimes, a minor adjustment can lead to significant results. Over time, you'll develop a feel for the right swing angles. It’s all part of mastering the craft of cutting.

| Material | Recommended Swing Angle (Degrees) | Cutting Speed (m/min) | Kerf Width (mm) | Saw Blade Type |

|---|---|---|---|---|

| Softwood | 5 | 20 | 1.5 | Wood Tooth |

| Hardwood | 10 | 15 | 1.8 | Tungsten Carbide |

| Plywood | 7 | 18 | 1.6 | Alternate Top Bevel |

| Metal | 15 | 10 | 0.5 | Bi-metal |

| PVC | 12 | 25 | 2.0 | Specialty Blade |

Tools and Techniques for Measuring Saw Swing Adjustments

Adjusting the saw swing is crucial for achieving better cutting accuracy. Measuring saw swing adjustments can be a challenging task, but with the right tools and techniques, you can improve your cuts significantly. A survey by the National Institute of Standards and Technology found that even slight inaccuracies in saw settings can lead to over 20% material wastage.

To begin, you need a reliable square and a caliper. The square ensures that your blade is aligned properly. Using the caliper, measure the distance from the back of the blade to the edge of the saw table. This gives you a baseline for adjustment. Digital angle finders are great for verifying the blade’s tilt. They help in ensuring precise adjustments while minimizing guesswork.

Tip: Always double-check your measurements. An error can snowball into larger issues later. Consider marking your adjustments clearly to track changes. Not all saws have the same adjustment features. Sometimes, it may require multiple attempts to get it right.

Using a dial indicator also aids in measuring swing more accurately. This tool can detect small deviations in blade position. It’s especially useful when fine-tuning your saw. Data suggests that consistent adjustments can improve cutting quality by up to 30%.

Tip: Develop a routine for adjusting your saw swing. Consistency in checking swing can save time in future projects. Remember, a small oversight now can lead to larger corrections down the line. Be patient with the process, and refine your technique gradually.

Step-by-Step Guide to Adjusting Your Saw's Swing Mechanism

Adjusting your saw's swing mechanism can greatly improve cutting accuracy. Follow these steps to achieve the best results. Begin by locating the swing adjustment knobs. These are usually found at the pivot points of the saw. Ensure the machine is turned off and unplugged before proceeding.

Next, check the current swing setting. Use a square to see if the blade aligns with the desired angle. If not, loosen the knobs slightly. Adjust the swing angle carefully. Tighten the knobs to secure the blade in place. It’s important to double-check the alignment after tightening.

Tips: Regular maintenance helps keep your saw accurate. Clean any debris around the swing mechanism. Small particles can affect the movement. Assess your adjustments after each use. Sometimes, even minor tweaks are needed for optimal performance. Remember, perfection takes practice. Test your cuts to ensure they meet your needs. Keep experimenting until you find what works best for you.

Common Mistakes to Avoid When Adjusting Saw Swing for Precision

When adjusting saw swing for precision, there are common mistakes to avoid. Many users overlook the importance of a stable base. A shaky surface can lead to inaccurate cuts. Always ensure your saw is on a level platform. Otherwise, your adjustments may not yield the desired results.

Another frequent error is neglecting measurements. Some practitioners make adjustments by eye alone. This often ends in disappointment. Use a reliable square or a measuring tool. Even slight inaccuracies can accumulate, leading to significant deviations in the cut.

Tips: Always double-check your angles before making final cuts. Small adjustments can make a big difference. It is easy to rush, but patience is crucial. Additionally, keep your tools clean and well-maintained. Dirty components can affect swing and ultimately your cutting precision. Don’t skip this step.