Edison LED Lighting

Projects

How to Choose the Best Stainless Steel Wire Mesh for Your Needs?

Choosing the right stainless steel wire mesh can be a daunting task. With various types available, each serves different purposes. The applications can range from industrial to personal use.

It's essential to consider your specific needs before making a decision. Think about the mesh size, wire diameter, and corrosion resistance. For instance, a finer mesh may be better for filtration. However, it may not be as durable as coarser options.

The quality of stainless steel wire mesh also plays a role. Not all products are created equal. Many items on the market may lack the durability you expect. This can lead to issues down the line. When you invest in stainless steel wire mesh, you want it to stand the test of time. Take the time to evaluate your options carefully.

Understanding Different Types of Stainless Steel Wire Mesh Available

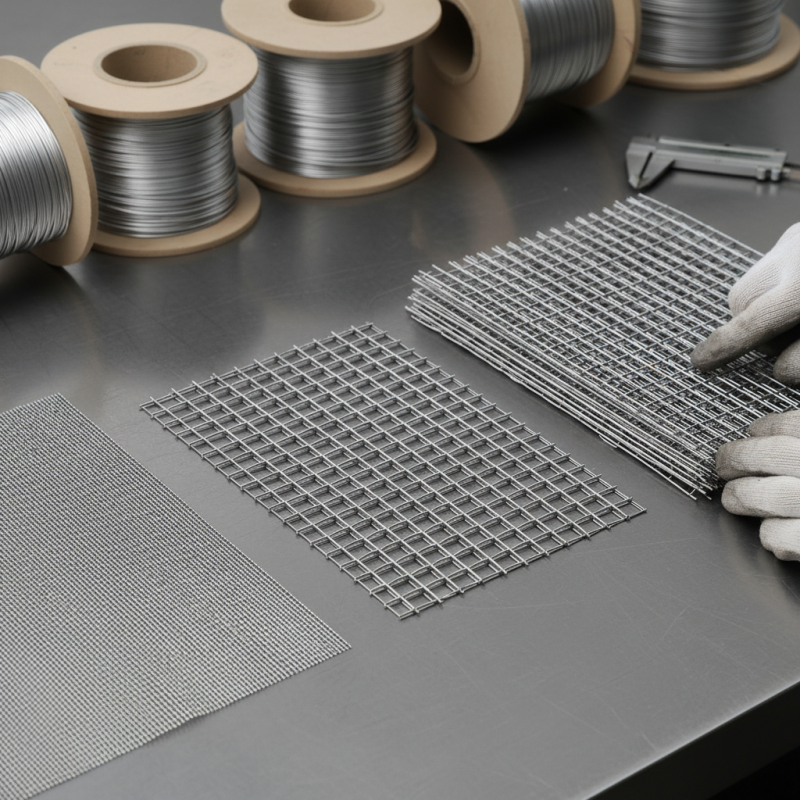

When selecting stainless steel wire mesh, understanding the types available is essential. Various mesh types cater to specific needs. Woven wire mesh is common, made from strands woven together, offering strength and durability. It’s often used in construction and filtration systems. Another popular option is welded wire mesh. This type consists of wires that are welded at intersections, providing increased stability and rigidity.

Fractional mesh sizes are vital for ensuring the right fit for your project. The higher the mesh count, the smaller the openings. It impacts the flow of air and liquids. You might find that some meshes can be too dense for certain applications. In contrast, a coarser mesh may allow unwanted materials to pass through.

Don't overlook finishes, either. They can significantly affect wire mesh performance. Some come with coatings for corrosion resistance. Depending on your environment, this can be crucial. The selection process may seem daunting, especially with so many choices available. Reflecting on your specific needs will help guide you to the right decision.

Understanding Different Types of Stainless Steel Wire Mesh

Factors to Consider When Selecting Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, several factors play a crucial role. The intended application is the first consideration. For example, if the mesh is needed for filtration, the size of the openings matters greatly. Smaller openings block fine particles, while larger ones allow more airflow. It's essential to identify the specific requirements before making a decision.

Another important factor is the wires gauge. Thicker wires offer more strength and durability. However, they may not provide the flexibility required for certain applications. On the other hand, thinner wires are more versatile but may wear out quickly under heavy use. Striking the right balance here is key.

Also, the environment where the mesh will be used influences its longevity. Corrosive environments demand higher grades of stainless steel. This might result in higher costs, yet it can prevent frequent replacements. It's easy to overlook these details. Rushing may lead to mismatched choices that don’t serve your purpose well.

Taking the time to evaluate these factors will yield better results.

Evaluating Wire Diameter and Opening Size for Your Project

Choosing the right wire diameter and opening size is crucial. These factors directly influence the performance of stainless steel wire mesh. The wire diameter impacts strength and flexibility. For example, a thicker wire provides more durability. A thinner wire, however, allows for finer openings and better ventilation.

Opening size, measured in microns or inches, determines what can pass through the mesh. A smaller opening filters particles effectively but might restrict airflow. Research shows that a 50-micron opening can filter out most bacteria. In contrast, a 200-micron opening allows for larger objects to pass. You must balance filtration efficiency and airflow based on your project needs.

It's also important to consider the intended environment. Factors like humidity and temperature can affect material choice. For some applications, a small opening might clog quickly. In those cases, a slightly larger opening with a strong wire makes sense. This creates a mesh that withstands wear but still meets filtration needs. Choosing the right specifications can be challenging, requiring careful design and material testing.

Assessing Corrosion Resistance and Material Grades in Mesh

Choosing the right stainless steel wire mesh involves understanding corrosion resistance and material grades. Corrosion resistance is crucial for longevity. Not all stainless steel is equal. Grades like 304 and 316 offer different levels of protection against rust.

304 stainless steel is widely used. It provides decent corrosion resistance in indoor conditions. However, it may not hold up in harsher environments. On the other hand, 316 stainless steel contains molybdenum. This addition improves resistance to corrosion, especially in chloride environments. It’s more expensive but often necessary for marine uses or chemical processing.

Tips: Always assess the environment where you will use the mesh. Will it face moisture? Consider 316 grade for optimal performance. In contrast, if the setup is indoors and dry, 304 can suffice. Each application demands careful thought. Don’t rush this decision; it affects the durability and safety of your project. Remember, choosing the right mesh can save future headaches.

Application-Specific Recommendations for Optimal Performance

When selecting stainless steel wire mesh, consider the specific application. Different environments need different types of mesh. For instance, a finer mesh works best in filtration applications. It captures small particles effectively. A coarser mesh is ideal for reinforcement. It provides strength in construction projects.

Think about the environment too. Corrosive settings require a higher grade of stainless steel. The right choice prevents premature failure. Also, remember the aesthetic aspect. In architectural applications, mesh can enhance design. Choose a weave that blends well with surroundings. Some patterns offer more light while others shield visibility.

User feedback can guide your decision. Sometimes, the best choice may not be obvious. Consult professionals if unsure. They can provide insights based on experience. Be prepared for trial and error. Adjusting your choice based on practical use is key. Aim for optimal performance, even if it means revisiting previous choices.

How to Choose the Best Stainless Steel Wire Mesh for Your Needs? - Application-Specific Recommendations for Optimal Performance

| Application | Wire Diameter (mm) | Mesh Count | Strength Rating (N/mm²) | Recommended Grade |

|---|---|---|---|---|

| Filtration | 0.5 | 100 | 450 | 304 |

| Safety Screens | 1.0 | 50 | 550 | 316 |

| Architectural Elements | 0.8 | 80 | 500 | 304 |

| Food Processing | 0.6 | 60 | 470 | 316L |

| Industrial Applications | 1.2 | 40 | 600 | 321 |