Edison LED Lighting

Projects

How to Choose a Switching Power Supply for Your Needs?

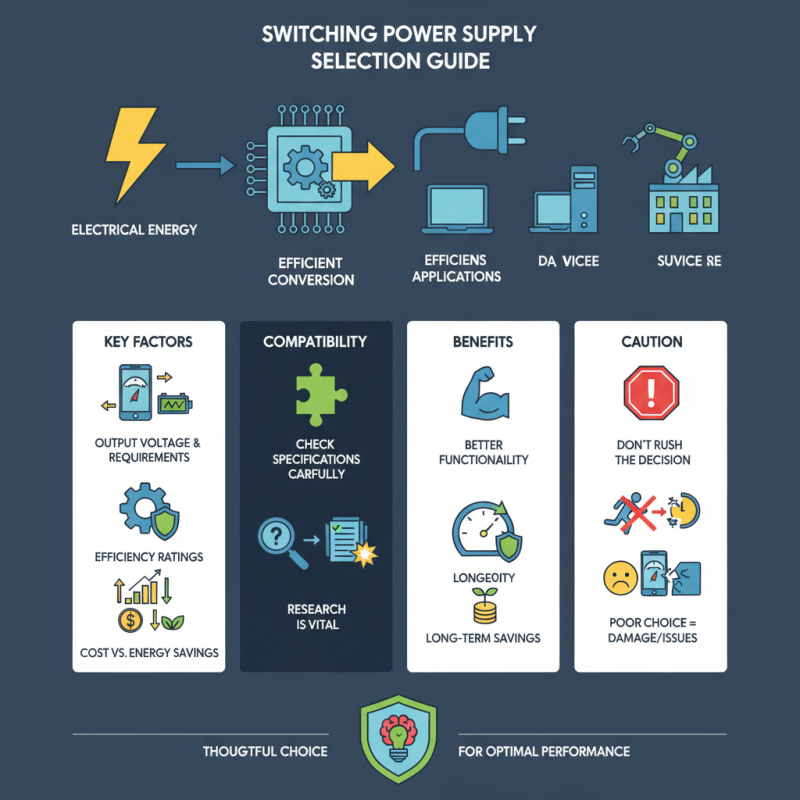

Choosing a Switching Power Supply can be challenging. It's essential to understand your specific needs before making a decision. These power supplies convert electrical energy efficiently. They are widely used in various applications, from consumer electronics to industrial settings.

When selecting a Switching Power Supply, consider factors like output voltage and current requirements. The quality of components can affect reliability. A poorly designed power supply might lead to performance issues. Consider the efficiency ratings as well. High-efficiency models save energy, but may cost more upfront.

Many users overlook compatibility with their devices. This can lead to inadequate performance or even damage. It’s vital to check the specifications carefully. Taking time to research will pay off in the long run. A thoughtful choice ensures better functionality and longevity. Don't rush this important decision.

Understanding the Basics of Switching Power Supplies

Switching power supplies (SMPS) are essential in modern electronics. They convert electrical power efficiently and are commonly used in various applications. Understanding their basics can help you choose the right one for your needs.

A switching power supply operates by switching on and off rapidly. This process reduces energy loss, making it more efficient than linear power supplies. According to industry reports, SMPS can achieve efficiencies exceeding 90%. This efficiency is crucial for devices that require long operational lifespans. Design choices in components, such as transformers and capacitors, significantly impact performance and reliability.

However, challenges exist in choosing the right SMPS. Not all supplies are created equal. Factors like output voltage, current rating, and load variation must be considered. Some users overlook thermal management, which can lead to reduced lifespan. Additionally, EMI concerns are vital. Inadequate design can result in significant interference with nearby electronics. Thus, reflecting on these considerations can lead to better decision-making when selecting a power supply for specific applications.

Identifying Your Power Requirements and Specifications

Choosing the right switching power supply involves understanding your specific power requirements. Start by determining the voltage and current your application needs. Calculate the total wattage by multiplying voltage by current. This ensures you won’t face power shortages or unexpected failures.

Consider whether you need a regulated or unregulated power supply. Regulated supplies provide consistent voltage and are ideal for sensitive devices. Unregulated options are sometimes cheaper but can lead to instability. Remember, your load requirements may fluctuate, so factor in a safety margin.

**Tips:** Always check the efficiency rating. A more efficient power supply generates less heat, prolonging its lifespan. Evaluate the dimensions and weight. They must fit your project space without compromising stability. Lastly, don't overlook cooling requirements for high-output models. Your design may need additional ventilation.

Power Supply Voltage and Current Requirements

Evaluating Efficiency and Performance Ratings

When selecting a switching power supply, efficiency and performance ratings are crucial. Efficiency indicates how well the power supply converts input to output. A higher efficiency means less energy waste. For example, a unit with 90% efficiency loses only 10% as heat. This can lead to lower electricity bills and cooler operation.

Check the performance ratings in the specifications. These may include ripple voltage, load regulation, and temperature stability. Ripple voltage should be low to prevent noise. Load regulation affects how well the supply maintains voltage under varying loads. Temperature variations can impact performance, especially in high demand situations.

Tips: Aim for a unit with at least 80% efficiency for general use. For sensitive electronics, consider a model with <1% ripple. Be cautious of high efficiency labels; they can be misleading. Research verified ratings before deciding. Every choice has trade-offs. Analyze what is best for your situation, but remember, perfection is rare.

Choosing the Right Form Factor and Design Type

When selecting a switching power supply, the form factor plays a vital role. The size and shape can affect installation and compatibility. Consider the space in your project. A compact design might be essential for limited spaces. On the other hand, larger models can provide better cooling and efficiency. Be practical in assessing your environment.

Different design types also bring unique advantages. Open-frame supplies are cost-effective and lighter but may lack protection. Enclosed models offer safety, but they occupy more space. The choice should reflect the project requirements. Sometimes, a wrong choice can lead to inefficient performance. Always think about the end usage when selecting the design type.

Don't overlook the mounting options as well. PCB or panel mounting can change the installation process significantly. Often, users choose based on preference rather than practical needs. Each option has its own implications for performance and safety. Reflecting on these details can prevent costly mistakes down the line. Remember, the right form factor and design can make all the difference in your project’s success.

Considering Safety Features and Regulatory Compliance

When selecting a switching power supply, safety features and regulatory compliance are crucial. According to a recent industry report, nearly 30% of power supply failures stem from inadequate safety mechanisms. These failures can cause overheating and even fires, leading to significant damage. Ensuring a power supply meets standards like UL, CE, and FCC can mitigate these risks.

Regulatory compliance also impacts product reliability. A study showed that equipment adhering to safety regulations lasts 20% longer than non-compliant counterparts. It is vital to review certifications specific to your region and application. Compliance signifies not just safety but also an adherence to efficiency guidelines, which can affect energy consumption significantly.

In the ever-evolving tech landscape, updates to safety standards occur frequently. Regularly evaluating your power supply’s compliance can be challenging. Sometimes manufacturers might not provide clear information. It leaves you pondering whether your choice is genuinely safe. Ensuring both safety and compliance is not merely a checkbox. It should be a core aspect of your selection process.

How to Choose a Switching Power Supply for Your Needs? - Considering Safety Features and Regulatory Compliance

| Feature | Description | Importance | Compliance Standards |

|---|---|---|---|

| Overcurrent Protection | Prevents excessive current from damaging the power supply. | Critical for device safety and longevity. | UL 60950, IEC 61010 |

| Overvoltage Protection | Shuts down the power supply in case of voltage spikes. | Essential for protecting connected devices. | CE, FCC |

| Thermal Protection | Monitors temperature to prevent overheating. | Helps prevent fires and malfunctions. | REACH, RoHS |

| EMI Filtering | Reduces electromagnetic interference for better performance. | Improves compliance with regulations. | CISPR 22, EN 55032 |

| Isolation | Separates output from input to enhance safety. | Critical for protecting users from electric shock. | IEC 60950, UL 1585 |