Edison LED Lighting

Projects

What is the Role of Aluminum Composite Panel Manufacturers?

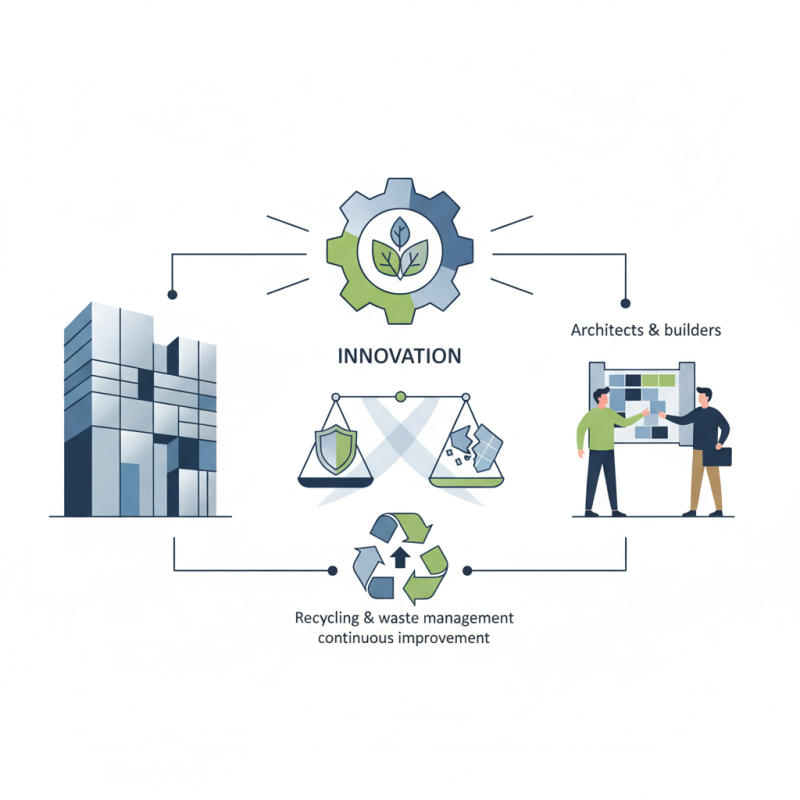

aluminum composite panel manufacturers play a crucial role in the construction and design sectors. Their innovative products combine aesthetic appeal with practical benefits. Architects and builders rely on these panels for various applications, including facades and interior designs.

These manufacturers focus on producing lightweight materials that offer excellent durability and insulation. Yet, challenges arise in balancing quality with cost. Some panels may lack in durability, leading to higher maintenance costs over time.

Moreover, sustainability is becoming increasingly important. Many aluminum composite panel manufacturers are now prioritizing eco-friendly practices. However, the industry still faces issues with recycling and waste management. Continuous improvement remains essential for the future of aluminum composite panels.

The Definition and Characteristics of Aluminum Composite Panels

Aluminum composite panels (ACP) are modern building materials. They consist of two thin layers of aluminum enclosing a non-aluminum core. This structure provides excellent durability and aesthetic appeal. ACPs are lightweight yet very sturdy. These properties make them popular in architecture and design.

The characteristics of aluminum composite panels include weather resistance and low maintenance. They can withstand extreme conditions without warping or fading. Additionally, their smooth surface allows for easy cleaning. However, not all ACPs perform equally. Some may not hold up under specific environmental challenges. This variability can lead to unexpected issues in long-term use.

In design, the options are vast. ACPs can be coated in various colors and finishes. This versatility allows architects to achieve unique looks. Yet, these creative choices can sometimes overshadow practical considerations. It's essential to balance aesthetics with functionality. Designers need to reflect on their choices carefully.

Key Manufacturing Processes of Aluminum Composite Panels

Aluminum composite panels are popular in construction and design. Their manufacturing process involves several critical steps that ensure quality. The process starts with the preparation of raw materials. Thin sheets of aluminum are cut to size. The core material, often made of a non-aluminum substance, is also shaped accordingly.

Next, the sheets are bonded to the core material. This step requires precision and attention to detail. Adhesives must cure properly to create a strong bond. Any oversight here can lead to delamination. After bonding, panels undergo a coating process. Protective finishes are applied to enhance durability and appearance. These coatings can vary in texture and color, adding to the aesthetic appeal.

Quality control is vital at every stage. Each panel must meet safety and performance standards. However, imperfections can still occur. Some panels may have surface defects or inconsistencies. Manufacturers must constantly evaluate their processes. Learning from mistakes is essential for improvement. Only by addressing these issues can manufacturers truly excel in creating aluminum composite panels.

Quality Control Measures in Aluminum Composite Panel Production

Quality control is crucial in aluminum composite panel production. Manufacturers must implement strict measures to ensure their products meet safety and durability standards. This involves regular inspection of raw materials, which include aluminum sheets and non-aluminum cores. A well-established procedure should be in place for checking the thickness, finish, and bonding strength of these materials.

Tips for quality assurance: Establish a checklist for each production stage. This can include visual inspections and testing for chemical resistance. Simple tools, like calipers, can help verify dimensions. Encourage workers to report inconsistencies. A quick response can save time and resources.

The production environment also matters. It should be kept clean to avoid contamination. However, it is common to overlook dust control. This can lead to defects in the finished product. Training staff in best practices can reduce these errors. Regular workshops keep everyone updated on quality standards. Balancing efficiency with careful attention to detail is key. This can sometimes lead to friction on the production floor, but it's essential for quality.

Market Demands and Trends Influencing Manufacturers

The aluminum composite panel market is experiencing significant changes. Manufacturers must adapt to various trends and demands. Energy efficiency is a major focus. Architects and builders want materials that reduce energy consumption. Lightweight panels are gaining popularity due to easier installation.

Sustainability is another key factor. Many customers prefer eco-friendly options. This influences manufacturers to explore recycled materials. However, sourcing sustainable materials can be challenging. Costs may rise, impacting pricing strategies.

Consumer preferences also shift towards customization. Clients seek unique designs and finishes. This trend pushes manufacturers to innovate their offerings. Yet, keeping up with rapid changes can be overwhelming. Companies must balance creativity with feasibility to stay competitive.

The Role of Manufacturers in Sustainable Practices and Innovations

Aluminum composite panel (ACP) manufacturers play a crucial role in promoting sustainable practices. The construction industry produces 39% of global carbon emissions, highlighting the need for innovation. ACPs, known for their lightweight and durability, can significantly reduce energy consumption in buildings. According to recent reports, the use of ACPs can cut energy costs by 30% during the operational phase.

Sustainability in manufacturing is not just a buzzword. It is a necessity. Many manufacturers are adopting eco-friendly materials and production techniques. A report from the Green Building Council indicates that sustainable materials can improve indoor air quality and reduce waste. However, not all manufacturers are adhering to these standards. Some still prioritize profit over sustainability. This inconsistency raises questions about accountability within the industry.

Innovation must go hand-in-hand with responsibility. The move towards recycled materials is commendable, but it is not enough. Manufacturers should also invest in research for better waste management processes. The challenge remains: how to balance profitability and environmental responsibility. Many companies are still figuring this out, often resulting in mixed outcomes.